Industry sectors and specialisation

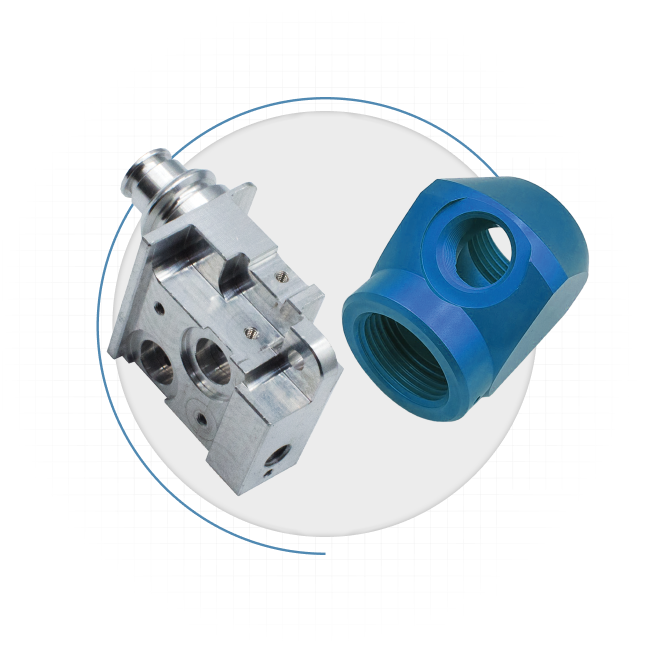

SPECIALISATION

We believe that specialisation is essential for a professional performance. We focus our efforts on several sectors (sensorics, hydraulics) in order to know and understand our customers’ needs perfectly.

In addition, we organise our processes according to selected product groups (volume, materials, geometry) in order to achieve maximum operational efficiency.

MILLING

MATERIAL

- aluminium

- non-ferrous metals

- synthetic materials

Quantity

- > 200 pcs

Dimensions

- X+Y+Z = max 400 mm

- X max = 250 mm,

- Y max = 250 mm,

- Z max = 100 m

Precision

- +/- 0,001 mm

TURNING - GROUP Ø40 & HYDRAULICS

Material

- steel

- stainless steel

- aluminium

- synthetics materials

Weight

- max 10 Kg

Quantity

- from several hundreds up to 1500 pcs

Dimensions

- steel D+L = max 200

- aluminium D+L = max 300

Precision

- +/- 0,001 mm

TURNING - FORGINGS & CASTINGS

Material

- steel

- stainless steel

- aluminium

- synthetics materials

Gewicht

- max 10 Kg

Quantity

- 1000 to approx. 20,000 pieces and more

Dimensions

- X+Y+Z max 400 mm

More complicated component

Material

- steel

- stainless steel

- aluminium

- brass

- synthetic materials

Quantity

- from a few to several thousand pieces

Dimensions

- 10 mm < D < 200 mm

Precision

- +/-0,02mm

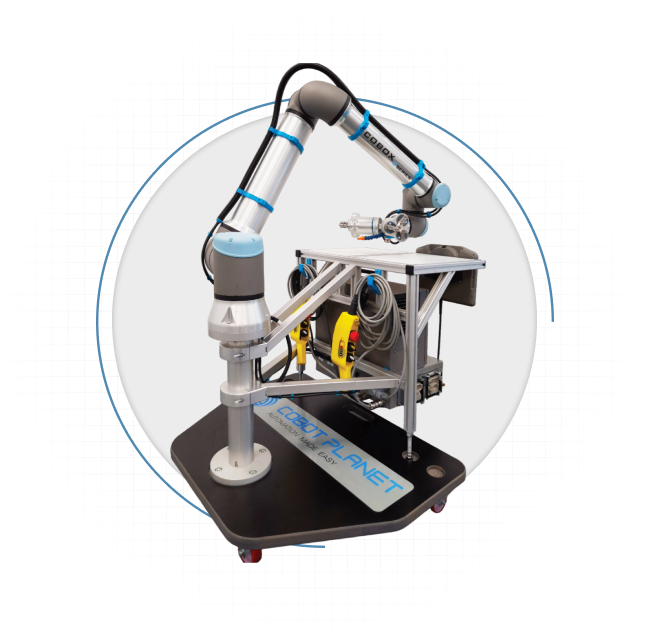

COBOX

COBOX

- Improvement of process stability

- Reduction of production costs

- Increase in OEE value Reducing the risk of machine downtime

- Deployment of the employee for activities with a high target value